Nitrogen Gas Generators

High purity & ultra high purity nitrogen generators for analytical applications

Highly versatile, with PSA or membrane technology, these generators are suitable for several analytical applications, ranging from laboratory (gas chromatography, liquid mass spectrometry) to industries. Complete range of solutions: from 500 cc/min to 120 l/min.

The Ultra High purity range produce laboratory high grade nitrogen for most of the laboratory applications and equipments. Designed with safety and convenience in mind, this system generates purified nitrogen, eliminating the need for inconvenient cumbersome high-pressure gas cylinders

Nitrogen or N2 gas is a slow gas used in many laboratories for analytical purpose

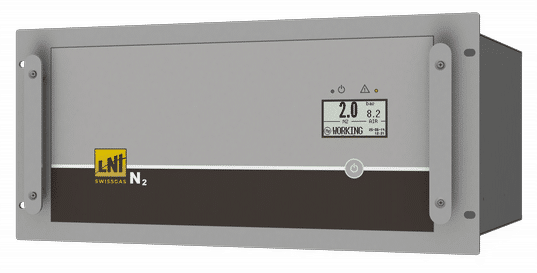

For more than 30 years LNI Swissgas has developed premium laboratory Nitrogen Gas Generators used in laboratories all over the world and suitable for several analytical applications, ranging from laboratory applications like gas chromatography, liquid chromatography and in particular LC-MS (Liquid Chromatograph-Mass Spectrometer), or sample evaporation to industries.

LNI offers a complete range of lab nitrogen generators. Our smart N2 gas generators can produce up to 99.9999% of pure nitrogen for your laboratory with flow-rates from 500 cc/min to 120 l/min.

The Ultra High purity (UHP) range of N2 generators produce laboratory high grade nitrogen for most of the laboratory applications and equipment.

Designed with safety and convenience in mind, these systems generate purified nitrogen, eliminating the need for inconvenient cumbersome high-pressure gas cylinders.

A nitrogen gas generator transforms standard compressed air into a safe, regulated supply of nitrogen and offer a cost-effective, reliable and green alternative to traditional nitrogen cylinders.

LNI’s nitrogen generators produce Nitrogen on-site and on-demand providing an uninterrupted supply of gas at the highest purity to the application.

LNI’s Nitrogen generators are based on two technologies: membrane and Pressure Swing Adsorption (PSA) technologies. Let’s discover them.

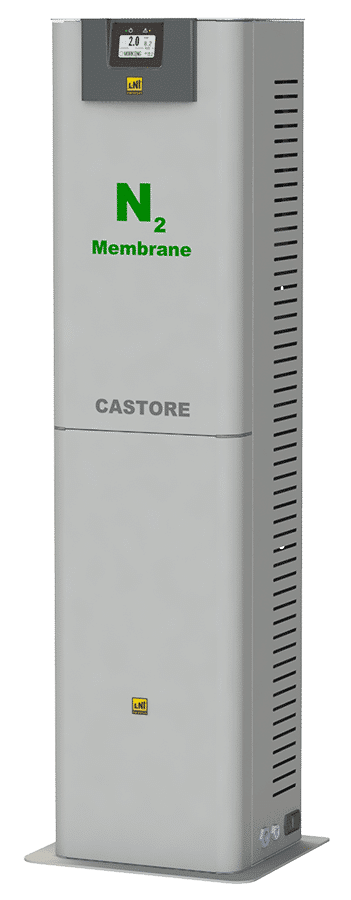

What is a Membrane nitrogen generator and how does it work?

A membrane nitrogen generator utilizes air pressure and a hollow fibre membrane to separate the N2 molecules from the others (including O2).

An air compressor pushes air through the membrane to filter it. Fibres are permeable to gas molecules and separate nitrogen (slow gas) from other fast gas including Oxygen, CO2, and water vapor.

The fast gases pass through the membrane and are exhausted in the atmosphere while the ‘slow’ gas, nitrogen, passes through the fibre more slowly, leaving only a high purity nitrogen.

Some systems remove other particles present in the gas such as dust and moisture before to reach the membrane filtration.

What is a PSA nitrogen generator (Pressure Swing Adsorption) and how does it work?

A PSA nitrogen generator (Pressure Swing Adsorption) utilizes Carbon Molecular Sieve (CMS) columns to adsorb oxygen under high pressure while allowing the nitrogen molecules to pass through the columns.

As one column is adsorbing oxygen and other molecules, the second column is depressurized, leaving a small amount of high purity nitrogen molecules.

LNI PSA nitrogen generators have higher purity capability than a membrane nitrogen generator.

Where is installed a lab nitrogen generator?

While gas cylinders are usually installed outside, a nitrogen gas generator can be easily and safely installed in the laboratory next to the instrument, on the floor or on a bench that LNI supplies and customizes. LNI in-house N2 generators are quiet and fit perfectly in the lab.

Benefits of On-Site Nitrogen Generators vs Nitrogen Gas Cylinders

Nitrogen gas cylinders are still used in many laboratories for analytical purpose.

They supply LC-MS instruments and other lab instrument, with a high volume of nitrogen where necessary, which means regular deliveries and changeover of bottles and with them, also critical analysis interruptions. Cylinders are cumbersome, unreliable and costly.

With lab gas generators, all of those problems are removed and the return of investment can be realised in a short time period.

Generators provide consistent and safe quantities of N2 gas to the lab instrument leaving only benefits over cylinders:

Safety and easy to use

Safety in a lab is paramount and on-site nitrogen generation is much safer than gas cylinders storage. A gas generator produces on-demand nitrogen at a controlled level and at low pressure. There is no risk of leaks. In the unlikely event of a leak, only a very small quantity of gas is released without any explosion risks.

A gas generator is more cost-effective than cylinders

Gas generators produce on-demand gas, eliminating gas wastage, delivery costs, cylinder rental charges, maintenance costs of cylinders, downtime costs, administration costs (re-order, prices increase) etc. Return on investment usually takes less than 1 year, depending on the application requirements (usage and purity).

- Deliveries and bottles changeover often cause critical downtime. With on-site gas generation, nitrogen is supplied to the application at the appropriate quantity, at the appropriate purity level and exactly when needed.

- Gas prices are unstable. With a lab gas generator on-site, the production of nitrogen is on-demand and does not depend on suppliers.

- Gas generators maintenance is easy and very low. Remote control avoids disassembly and allows the manufacturer to analyse critical equipment parameters as well as identify pending failures before they affect your lab operations.

- Gas generators of LNI have an energy savings competitive advantage when compared to others.

A gas generator is a green solution

- On-site gas generators reduce carbon footprint. A small and light machine with a push button next to your instrument replaces thousands of hazardous gas cylinders.

- On-site gas generation uses renewable resources air and water

- On-site gas generators eliminate gas deliveries forever

- The remote diagnostics capability on our products helps us to support our customers quickly while avoiding travel, whenever possible, and the environmental impact it imposes on our planet.

- Our products utilize technology with energy savings features

LNI nitrogen generators are an economical and safe alternative to high pressure gas cylinders in laboratories. The high performance of our generators makes them the solution for laboratory applications providing high purity nitrogen and ultra-high purity nitrogen to the application.

References:

1. https://en.wikipedia.org/wiki/Nitrogen

2. https://en.wikipedia.org/wiki/Nitrogen_generator#Membrane_technology