HG PRO

PEM Hydrogen generator

The HydroGen series HG PRO is able to generate up to 1500 cc/min of Hydrogen with purity better than 99.99999% and pressure up to 16 bar (232 psi). The HG PRO includes a new long life multilayer electrolytic cell with polymeric membrane (PEM) using distilled water. No acid or alkaline solutions are used.

The innovative gas drying system (two-column drying PSA system with automatic regeneration) ensures the maximum grade of hydrogen purity, it is completely maintenance-free and allows continuous operation, 24 hours a day. The on-board CPU automatically check for internal leaks and constantly control the operating parameters to guarantee full safety.

Up to 20 units can be connected in parallel using an external control box. The touch-screen LCD interface provides simple and user-friendly management of all functions on the unit.

Stackable with various other models: AG-OFCAS35; NG-EOLO; AG-ZA-Fid

Product features

- New long life multilayer PEM cell

- High flow rate up to 1500 cc/min

- High pressure up to 16 bar (232 psi)

- RS 232/485 and USB standard

- LAN optional

- Auto refill standard

- High purity: 99.99999%

- Dryer with no maintenance

- Safety routine and self monitoring

- Reduced foot print

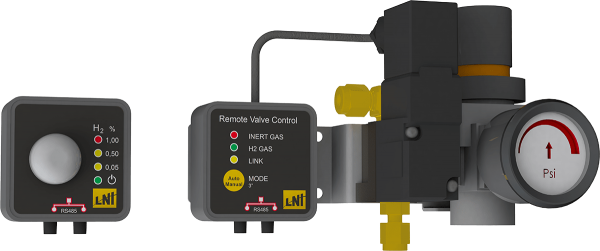

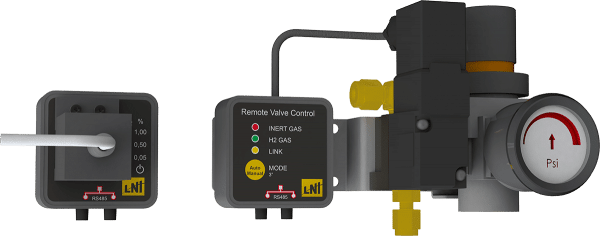

- High pressure GLS electronically controlled (patented)

Main applications

- Carrier gas for GC and GS-MS

- GC-FID / GC-NPD / GC-FPD / THA

- ICP-MS collision gas

- Refilling metal hydride tanks for use with fuel cells

Technical specifications

| Models: HG PRO | 120 | 180 | 260 | 350 | 500 | 700 | 900 | 1100 | 1300 | 1500 |

| General data | ||||||||||

| Electrolytic cell | Long life Multilayer PEM technology | |||||||||

| Drying system | PSA (Pressure Swing Adsorption) | |||||||||

| H2 purity | >99.99999% * | |||||||||

| Outlet pressure | 12 bar (174 psi) / 16 bar (232 psi) (optional) | |||||||||

| H2 flow-rate (Max) | 120 | 180 | 260 | 350 | 500 | 700 | 900 | 1100 | 1300 | 1500 |

| Dimensions | 27 x 44 x 41(H) cm | |||||||||

| Net weight (no water in tank) | 20 kg | 22.5 kg | 25 kg | 26 kg | ||||||

| Communication | ||||||||||

| RS-232 / USB / RS-485 | Standard | |||||||||

| Digital I/O | Standard | |||||||||

| LAN | Optional | |||||||||

| Software functions | ||||||||||

| Parallel mode | Ready on board | |||||||||

| Automatic tank refill | Standard | |||||||||

| Fill Hydride canister function | Standard | |||||||||

| Water | ||||||||||

| Quality Required | Deionized, ASTM II, <0.1uS | |||||||||

| Supply pressure (min, Max) | 0.1 bar (1.45 psi), 0.5 bar (7.25 psi) | |||||||||

| Supply flow rate (min, Max) | 0.2 l/min, 1.5 l/min | |||||||||

| Internal tank capacity | 3 L | |||||||||

| External tank capacity | 5 or 10 L (optional) | |||||||||

| Electrical data | ||||||||||

| Type of connection | IEC 320-C14 | |||||||||

| Power supply voltage | 100-240 Vac (±10%) 50/60 Hz | |||||||||

| Nominal power (Max) | 320W | 600W | 750W | |||||||

| Fuse rating (5×20) | 4A (250 Vac – T) | 6.3A (250 Vac – T) | ||||||||

| Connections | ||||||||||

| Hydrogen outlet | 1/8” compression fitting | |||||||||

| Water | Quick release push-in fitting | |||||||||

| Operating/storage conditions | ||||||||||

| Working Temperature | 5-40°C (41-104°F)** | |||||||||

| Storage Temperature | 1-50°C (34-122°F) | |||||||||

| Humidity (max, non condensing) | 70% | |||||||||

| Noise | < 35dB(A) | |||||||||

| IP rating | IP20 | |||||||||

| Pollution degree rating | 2 (with no aromatic compounds) | |||||||||

| Altitude | < 2000 m | |||||||||

* referred to O2, dew point <-75°C (< -103°F), Atmospheric Dew Point (ADP)

** with temperature > 35°C the H2 purity could be less

Information request

Need more information about this product?

Please contact us at info@lni-swissgas.eu or fill the form.